A supply chain consultant is far more than an external advisor; they are a strategic partner engaged to diagnose, architect, and implement enhancements to a company's entire operational backbone. Their mandate is to drive efficiency, fortify resilience, and ultimately, elevate profitability. By navigating the complexities of global markets and integrating advanced technologies like Artificial Intelligence, they help sharpen an organisation's competitive edge. For German enterprises facing today’s unprecedented volatility, this role has become mission-critical.

Navigating the New Mandate for Supply Chain Excellence

The established principles of global trade have been fundamentally disrupted. Geopolitical friction, abrupt regulatory shifts, and volatile consumer demand have exposed the vulnerabilities of traditional supply chains engineered purely for cost minimisation. For leaders within Germany’s industrial sector, the imperative is clear: legacy optimisation models are no longer sufficient.

This new reality has reshaped the function of a supply chain consultant. The scope has expanded from a narrow focus on process optimisation and cost reduction to a broader, strategic mission. Today's consultant is an architect of resilience, a driver of digital transformation, and a catalyst for tangible innovation.

From Advisor to Strategic Partner

The traditional consulting model—delivering a comprehensive report with recommendations—is now obsolete. A modern partner is expected to engage directly with implementation, delivering measurable operational outcomes. Their value is assessed not by the elegance of their strategy, but by the tangible performance improvements they help achieve.

This evolution is evident across several key domains:

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

- Proactive Risk Mitigation: Modern consultants design systems that anticipate and absorb disruptions—from raw material shortages to regulatory changes—rather than merely reacting to crises.

- Digital Ecosystem Integration: They serve as integrators, connecting legacy systems with a future-ready digital infrastructure to enable a seamless flow of data from suppliers to end customers.

- AI Implementation: This involves the practical application of AI to solve specific business challenges, such as leveraging predictive analytics for demand forecasting or automating logistics to eliminate bottlenecks.

The objective is no longer incremental efficiency gains. It is to construct an intelligent, adaptive supply network that functions as a core competitive advantage for the entire enterprise.

An Innovation Catalyst for German Enterprises

For Germany’s medium-sized and large enterprises, a top-tier supply chain consultant is an indispensable partner for navigating complexity and securing future growth. They provide an objective perspective that can challenge conventional thinking and accelerate the adoption of new technologies.

By engaging an expert consultant, an organisation gains a co-pilot capable of translating high-level business objectives into concrete operational actions. They provide the strategic roadmap, the technological tools, and the hands-on support required to transform the supply chain from a cost centre into a powerful engine for innovation and market leadership. You can explore further insights on how supply chain consulting unlocks strategic advantages.

Mapping Core Services to Business Objectives

Engaging a supply chain consultant represents a significant investment. Its success hinges upon the precise alignment of their engagement with your specific business objectives. Without this explicit linkage, a project risks becoming a theoretical exercise with limited real-world value.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

For senior leaders, the initial step is to distinguish between the two primary modes of consulting engagement: Strategy and Operations.

Understanding this distinction is critical. These engagements address different problems, operate on different timelines, and yield distinct outcomes. Correctly identifying the required expertise ensures that consulting expenditure becomes a high-return investment rather than a sunk cost.

This is particularly relevant in the German supply chain consulting market, valued at approximately USD 1.4 billion and dominated by the manufacturing sector. The prevailing pressures are to streamline production, enhance visibility, and manage persistent risks. Strategic consulting is paramount in this context, helping companies align their supply chains with corporate goals and navigate complex regulations. Operations consulting, in contrast, focuses on achieving immediate improvements in cost efficiency and operational resilience.

Strategic vs Operational Engagements

To clarify the distinction, it is useful to compare these two engagement types. One focuses on designing the blueprint for future operations, while the other optimises the existing machinery.

| Engagement Type | Primary Objective | Typical Activities | Key Deliverables | Ideal For |

|---|---|---|---|---|

| Strategy Consulting | Design a future-proof supply chain that supports long-term corporate vision. | Network modelling, market analysis, technology roadmapping, regulatory impact assessment. | 3-5 year roadmap, network design blueprint, business cases for major investments. | Companies planning major expansion, facing new regulations, or needing a long-term competitive edge. |

| Operations Consulting | Achieve immediate, measurable improvements in cost, efficiency, and service levels. | Process mapping, bottleneck analysis, inventory optimisation, logistics cost reduction. | Optimised process flows, cost savings reports, improved inventory models. | Businesses looking to reduce operational costs, improve efficiency, and solve specific performance issues quickly. |

Ultimately, the choice of engagement depends entirely on the specific problem your organisation must solve now. Is the objective to build for the next decade, or to resolve a costly operational issue by the next quarter?

Strategic Consulting: Architecting Your Long-Term Vision

Strategic consulting is analogous to the architectural design of your entire supply network. It provides a top-down perspective to address foundational questions about the company's future direction and the operational infrastructure required to support it. This work is inherently forward-looking, typically spanning a 3-5 year horizon.

A strategy consultant helps address high-stakes questions:

- Network Design: Where should facilities be located to optimally balance cost, speed, and resilience against geopolitical risks?

- Regulatory Compliance: How can the supply chain be re-engineered to comply with stringent new standards like the EU Green Deal or Germany’s Supply Chain Act (LkSG) while maintaining profitability?

- Technology Roadmaps: Which emerging technologies—such as AI or IoT—should be prioritised over the next five years to build a sustainable competitive advantage?

The deliverable is not a quick fix but a comprehensive roadmap, a detailed network model, or a robust business case for significant capital investment. This is the C-level analysis required to ensure the company’s long-term viability and market position.

A strategic engagement defines the 'what' and 'why' of your supply chain transformation. It establishes the blueprint that will guide your operational decisions for years to come, ensuring every initiative supports the overarching corporate vision.

Operations Consulting: Driving Immediate Impact

If strategy is the architect, operations consulting is the master engineer focused on the performance of the existing system. This bottom-up approach identifies immediate, measurable improvements in efficiency, cost, and service levels. The timeline is significantly shorter, with value delivered within months rather than years.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

An operations consultant addresses granular, on-the-ground challenges:

- Process Optimisation: How can bottlenecks in the warehouse-to-customer workflow be eliminated to reduce lead times by 15%?

- Cost Reduction: Where are the latent inefficiencies in logistics and purchasing that are eroding margins? Implementing effective procurement cost reduction strategies is often a core focus here.

- Inventory Management: Can improved forecasting models reduce excess stock and its associated carrying costs without increasing the risk of stockouts?

For example, in the automotive sector, an operational consultant might analyse a just-in-time production line to identify micro-delays that, once resolved, yield significant gains in throughput.

The most formidable supply chains are created when strategic vision is integrated with operational excellence. This synergy produces a system that is both resilient for the future and ruthlessly efficient today. To gain a deeper understanding of this dynamic, you can explore how strategy and technology intersect to drive performance.

Using AI to Tackle Systemic Labour Challenges

Germany's industrial strength has historically been built upon its highly skilled workforce. This foundation is now under significant pressure. The persistent shortage of qualified labour is no longer a distant threat but a present-day constraint impacting businesses nationwide.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

This challenge is particularly acute in core industrial sectors. A recent FTI Consulting Supply Chain Barometer reported that 77% of German companies are contending with skilled worker shortages, a concern second only to cost inflation. This is evident daily in manufacturing and automotive, where the talent gap directly constrains production and stifles innovation. You can review the full research on supply chain pressures from FTI Consulting.

For senior leaders, the question has evolved from if this will affect operations to how to build a business resilient to it. This is where a modern supply chain consultant plays a pivotal role. Their function now extends beyond process optimisation to the strategic deployment of targeted AI solutions to address these critical labour gaps.

The objective is not to replace human capital but to augment its expertise and amplify its impact, thereby transforming a significant vulnerability into a competitive advantage.

Deploying AI Co-Pilots to Augment Planning Teams

Complex logistics planning is one of the first functions to experience the impact of a diminished talent pool. Seasoned planners possess invaluable institutional knowledge but are often encumbered by repetitive, data-intensive tasks. This administrative burden consumes their time and diverts focus from higher-value strategic activities.

This environment is ideal for the introduction of AI.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

An expert consultant can design and implement AI co-pilots—intelligent assistants that work alongside human teams. These are not replacements but powerful force multipliers.

These co-pilots can automate computationally intensive tasks, such as:

- Route Optimisation: Continuously analysing thousands of variables—traffic, weather, delivery windows—to determine optimal routes in real-time.

- Load Planning: Calculating the most efficient methods for packing containers and vehicles to reduce transport costs and emissions.

- Supplier Scheduling: Automatically coordinating inbound materials to prevent bottlenecks in the production line.

By delegating this computational work to AI, experienced planners are free to manage high-value exceptions, make strategic network decisions, and cultivate stronger supplier relationships.

The consultant's role here is twofold: first, to identify the precise planning workflows where an AI co-pilot will deliver the greatest impact, and second, to engineer and deploy a secure, self-hosted system that integrates seamlessly with existing ERP and TMS platforms.

Introducing Intelligent Automation to the Warehouse

The labour shortage is felt with equal intensity on the warehouse floor. Recruiting and retaining personnel for physically demanding roles in picking, packing, and sorting is a persistent challenge that creates operational instability. A supply chain consultant can introduce intelligent automation to bridge this gap.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

This extends beyond basic conveyor systems to the deployment of autonomous mobile robots (AMRs) that navigate busy warehouse environments to transport goods, or AI-powered vision systems that identify quality control issues with superhuman accuracy.

Implementing these systems is not merely a technology project; it is a fundamental operational transformation. A consultant guides the entire process, from business case development to full implementation, ensuring the solution is perfectly aligned with the facility's layout, product mix, and workflows. This is a crucial step in preparing operations for the future of working.

Using NLP to Enhance Supplier Communication

Finally, consider the significant effort required to manage a global supplier network. Constant communication is critical but also immensely time-consuming. Natural Language Processing (NLP), a branch of AI, can automate and enhance these interactions around the clock.

A consultant can help implement NLP-based systems to:

- Monitor Supplier Communications: Automatically scan incoming emails for urgent issues like production delays or quality alerts, flagging them for immediate human intervention.

- Automate Routine Inquiries: Handle standard questions regarding order status or payments, freeing up procurement teams for more strategic negotiations.

- Analyse Sentiment: Gauge supplier sentiment by analysing communication patterns, enabling the early detection of at-risk relationships.

By integrating AI into these core functions, you can build a supply chain that is more responsive, resilient, and efficient—one that is less dependent on the availability of skilled personnel. An experienced consultant is the partner who facilitates this transformation, translating the promise of AI into tangible solutions for one of German industry’s most pressing problems.

Turning Data Analytics Into a Competitive Edge

Data is no longer a by-product of operations; it is the most valuable asset for building a predictive and resilient supply chain. For German companies, where precision and efficiency are integral to corporate identity, converting raw data into strategic intelligence is not merely an upgrade—it is a competitive necessity.

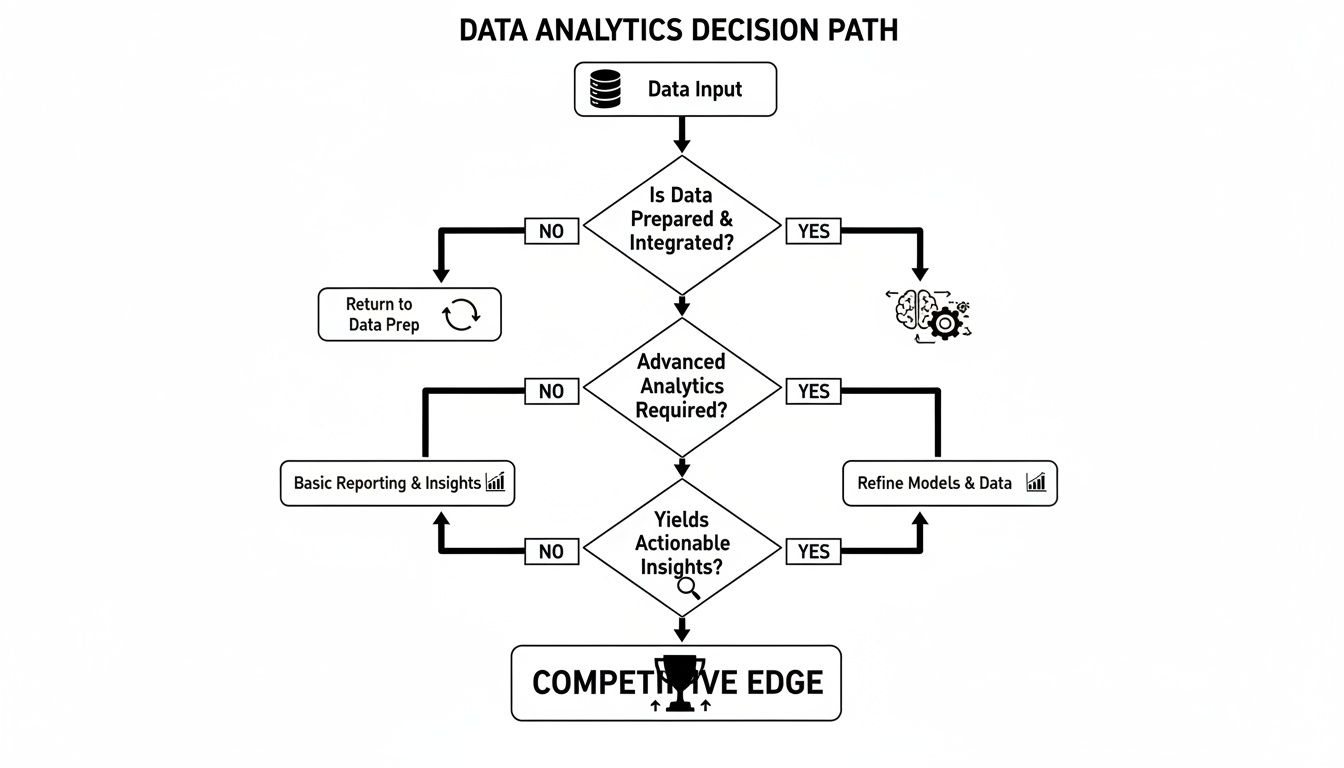

A supply chain consultant serves as the translator in this process. They transform streams of operational data into a clear, actionable plan that confers a competitive advantage. This extends beyond creating dashboards; it involves architecting a robust data infrastructure that delivers real-time insights, enabling teams to make smarter, faster decisions. The objective is to transition from a reactive, fire-fighting posture to a proactive, data-driven strategy.

From Raw Data to Actionable Strategy

The journey from data accumulation to competitive advantage is a multi-stage process. An expert consultant guides this journey, ensuring technology investments yield tangible business outcomes. It should be viewed as a methodical process, not a singular project.

The core components of this transformation typically include:

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

- Production-Ready Data Pipelines: These are the digital arteries of the supply chain, consolidating information from ERPs, warehouse management systems, and IoT sensors into a unified, usable format. A consultant ensures these pipelines are not only functional but also secure and scalable enough to handle real-time data without failure.

- Predictive Analytics for Demand Forecasting: Moving beyond simple historical averages is essential. Predictive models employ machine learning to analyse complex variables—market trends, seasonality, promotional impacts—to forecast demand with significantly higher accuracy. This reduces both costly overstocking and revenue-losing stockouts.

- Machine Learning for Network Optimisation: Machine learning algorithms can analyse millions of scenarios to identify the optimal configuration for a logistics network. This includes determining the most efficient shipping routes and rebalancing inventory across distribution centres in response to shifting demand.

A consultant's primary role is to de-risk and accelerate this digital transformation. They bridge the gap between your team's operational expertise and the complexities of data science, ensuring every analytics project is directly focused on solving your most critical business challenges.

Capturing Germany’s Analytics Advantage

The strategic importance of data analytics is underscored by Germany's leadership in this field. Germany dominated Europe's supply chain analytics market in 2023 and is projected to reach USD 1,671.7 million by 2031. This growth is driven by the country’s high-tech production sales, which increased from €271 billion in 2013 to €406 billion in 2023. This increasing complexity fuels demand for experts who can build sophisticated data systems and apply AI for real-time optimisation. For a closer examination of these market dynamics, further details are available in the European supply chain analytics market research.

An effective consultant helps you leverage this trend. By implementing advanced analytics, they provide your teams with the tools to manage complexity proactively. This creates a powerful feedback loop: superior data leads to better decisions, which in turn generate more valuable data. For those interested in how specific tools can uncover hidden inefficiencies, our guide on process mining with Celonis offers valuable insights.

Ultimately, weaponising analytics requires embedding a data-first mindset into the fabric of your supply chain. It demands the right strategy, technology, and partner. With this combination, your supply chain transforms from a cost centre into an intelligent, proactive engine for growth.

A Decision Framework for Selecting the Right Partner

Selecting a supply chain consultant is a critical business decision. It is not merely a procurement exercise; you are engaging a partner with the potential to fundamentally reshape your company’s operations. For senior leaders in Germany, the primary challenge is not evaluating polished presentations, but identifying a partner who will deliver tangible, sustainable value.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

The traditional consulting model is no longer adequate. Receiving a comprehensive report and a valediction is insufficient for today's complex challenges. Modern supply chain issues demand a partner who shares accountability for outcomes and is as invested in your success as you are. This represents a shift from a transactional relationship to a genuine partnership.

From Traditional Advisory to Modern Partnership

The right partner does not simply offer advice; they actively build and implement solutions. This is a crucial distinction when evaluating potential consultants. You require demonstrable proof of their ability to translate a strategic concept from a whiteboard into a fully implemented system, particularly when complex AI is involved.

A true strategic partner accepts shared responsibility for outcomes. Their success is measured not by the quality of their recommendations, but by the measurable improvements they help you achieve in your operations, from cost reduction to increased production throughput.

To identify a partner with this mindset, you must probe beyond standard criteria like industry experience or pricing. The focus must be on execution capability, cultural alignment, and their plan for empowering your internal team.

Critical Evaluation Criteria For Your Shortlist

When designing or overhauling a supply chain, a significant part of the process involves selecting the right logistics partners, similar to determining the best courier service Australia for an e-commerce business; a robust framework is needed. Your approach to selecting a consulting partner should be equally rigorous.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

To structure this evaluation, we have developed a checklist. A robust vendor due diligence process is your primary defence against risk. To explore this topic further, you can learn more about conducting effective vendor due diligence in our detailed guide.

Consultant Selection Checklist

Choosing the right consulting firm is a pivotal decision. This checklist is designed to penetrate sales rhetoric and focus on what is essential: finding a partner with proven delivery capabilities.

| Evaluation Category | Key Questions to Ask | Ideal Response / 'Green Flag' | Warning Signal / 'Red Flag' |

|---|---|---|---|

| Implementation Capability | Do you have in-house engineers and data scientists, or do you outsource? Can you provide examples of production-ready systems you have built? | "Yes, our in-house team built and deployed these specific projects..." (Provides case studies). | "We partner with a network of implementation specialists..." (Vague about who performs the work). |

| Accountability Model | How are your fees structured? Are you open to performance-based contracts tied to KPIs? | "A portion of our fee is directly tied to achieving targets like X% cost reduction or Y% efficiency gain." | A rigid, fixed-fee model with no shared risk. Reluctance to link fees to results. |

| Cultural & Methodological Fit | What is your project management methodology? Agile or waterfall? | "We use agile sprints to deliver working prototypes quickly, gathering feedback iteratively." | A long, linear "waterfall" plan with no tangible deliverables for several months. |

| Team Enablement & Knowledge Transfer | What is your plan for upskilling our team? How do you ensure we are not dependent on you long-term? | "We conduct joint workshops and pair-programming sessions. Our goal is for your team to own the solution." | No clear plan for knowledge transfer. The consultant becomes a permanent dependency. |

By asking these incisive questions upfront, you can gain a much clearer understanding of the partner you are engaging and avoid a costly misalignment.

Vetting AI Expertise and Security Posture

Two areas demand particularly close scrutiny today: artificial intelligence and security. Any consultant proposing AI solutions must be capable of answering specific, rigorous questions.

First, assess their AI proficiency. Request a detailed walkthrough of their process, from translating a business concept into a testable AI hypothesis to deploying a production-ready application. You are looking for a clear, low-risk methodology that incorporates rapid prototyping and validation before committing to a full-scale build.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

Second, rigorously evaluate their security and compliance posture. For any German company, especially within the automotive sector, TISAX (Trusted Information Security Assessment Exchange) compliance is non-negotiable.

Here are essential security questions to begin your inquiry:

- Can you provide your own security certifications, such as ISO 27001 or TISAX?

- How do you ensure our data remains segregated and confidential from that of your other clients?

- What is your protocol for handling our sensitive operational data, both in transit and at rest?

Selecting the right supply chain consultant is a foundational business decision. By employing a structured framework that prioritises implementation capability, shared risk, and a robust security posture, you will identify a partner who does not just theorise about innovation—they help you build it.

The Practical Questions: Budgets, Timelines, and Your Team

Let us now address the practical considerations. Beyond strategy presentations and future-state diagrams, a consulting engagement comes down to three core elements: budget, timeline, and the commitment of your own personnel. As a leader, you require unambiguous answers to these questions before committing. Below are the most common inquiries from German businesses, answered directly.

What Is the Anticipated Cost?

The traditional model of opaque hourly billing is outdated. Modern consulting pricing should be predicated on predictable value. While some consultants may still quote day rates, leading firms have transitioned to models that align their financial success with yours.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

Two primary structures are common:

- Fixed-Fee for a Defined Scope: This provides the greatest budget certainty. For a well-defined project, such as a network analysis or a warehouse process re-engineering, you receive a single, all-inclusive price.

- Performance-Based Fees: This model directly links a portion of the consultant's compensation to the achievement of specific, measurable outcomes. Examples include a percentage of realised cost savings, a quantifiable reduction in inventory levels, or a defined improvement in on-time delivery rates. This structure ensures the consultant has a vested interest in the project's success.

When reviewing a proposal, demand complete transparency. The fee structure must explicitly detail all inclusions. Does it cover implementation? Team training? Ongoing support? A genuine partner will welcome this level of scrutiny.

What Is the Projected Timeline?

The answer is contingent upon the project's scope. A rapid strategic diagnostic may be completed in four to eight weeks. A full-scale technology implementation could extend over several months.

The key, however, is to avoid large, monolithic projects that deliver no value for extended periods. This approach is particularly risky for AI and data initiatives. The correct methodology is to break the project into short, focused sprints. This allows for continuous progress monitoring, feedback, and course correction.

A well-structured, phased plan typically includes:

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

- Discovery & Business Case (2-4 weeks): An intensive analysis to identify the highest-impact opportunities, model the potential ROI, and define the precise problem to be solved.

- Prototype & Validation (4-6 weeks): The development of a working model or a minimum viable product (MVP). This step is critical to prove the concept's viability and value before committing to a full-scale deployment.

- Scale-Up & Handover (3-6 months): The rollout of the validated solution across the broader organisation. This phase must include comprehensive training to enable your team to operate the system independently.

Insist on a project plan with clear milestones. This provides regular checkpoints and ensures value is delivered incrementally, rather than being delayed until a final "big bang" delivery.

What Is the Required Time Commitment from My Team?

A consulting project is a partnership, not a task to be fully outsourced. A project undertaken in a silo is destined to fail.

The involvement of your internal team is the single most critical success factor. They possess the deep, tacit knowledge of how operations function in reality. The consultant contributes specialised skills, proven methodologies, and an external perspective to challenge entrenched assumptions.

You will need to assemble a core internal team:

- An Executive Sponsor: A senior leader with the authority to remove obstacles and maintain the project's visibility at the C-suite level.

- A Project Manager: The day-to-day point of contact responsible for internal coordination.

- Subject Matter Experts (SMEs): Key individuals from logistics, procurement, IT, and finance who possess detailed operational knowledge.

The time commitment will be most intensive during the initial discovery phase and the final rollout, but consistent engagement is required throughout.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The hallmark of an exceptional supply chain consultant is that they ultimately make themselves redundant. Their objective should not be to create a perpetual dependency. It should be to transfer knowledge and skills, empowering your team to own, manage, and continuously improve upon the solution long after the engagement concludes.

At Reruption GmbH, we operate as co-preneurs. We share the risk and accountability for transforming ambitious ideas into production-ready AI that delivers tangible business value. We build solutions for real-world challenges—from supply chain disruptions to labour shortages—to prepare your business for the future. Discover how our hands-on approach delivers measurable results.