For Germany's industrial leaders, supply chain resilience is no longer a strategic option—it is the foundation of competitive advantage. The discipline of supply chain consulting has evolved beyond tactical cost reduction. Today, it centres on forging intelligent partnerships that enable organisations to master global volatility through AI-powered systems, thereby securing a sustainable market position.

The New Competitive Imperative in Supply Chain Consulting

The established playbook for supply chain management, predicated on lean principles and just-in-time inventory, proved inadequate against the pressures of recent global disruptions. For executives in Germany’s automotive and manufacturing sectors, the mandate has shifted. The focus is no longer solely on efficiency; it is on architecting antifragile operations capable of anticipating and absorbing systemic shocks.

This new reality necessitates a fundamental redesign of operational frameworks. The analogy is akin to upgrading a vehicle's powertrain. While a conventional engine was reliable under predictable conditions, a modern smart hybrid system leverages real-time data to continuously optimise power and efficiency for any contingency. This represents the strategic leap required.

Shifting From Reaction to Prediction

At its core, modern supply chain consulting facilitates the transition from reactive problem-solving to proactive, data-driven foresight. Analysing historical performance reports is no longer sufficient. Market leadership now belongs to companies that can accurately predict future demand, identify potential supplier vulnerabilities preemptively, and model the financial impact of geopolitical shifts with precision.

This is where Artificial Intelligence becomes an indispensable capability. AI-powered systems can analyse vast, complex datasets—from weather patterns and consumer sentiment to machine sensor data—to uncover risks and opportunities beyond the scope of human analysis.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The purpose of advanced consulting is to embed intelligence directly into an organisation's operational DNA. The goal moves from knowledge transfer to continuous enablement, ensuring the enterprise can sustain decision intelligence long after the engagement concludes.

A New Paradigm for Partnership

As supply chains increase in complexity, the demand for expert general consulting services has intensified, redefining the prerequisites for competitive advantage. This shift also redefines the consultant's role from an external advisor to an integrated partner.

Success is not measured by a strategic document; it is measured by the implementation of production-ready systems that deliver tangible ROI. A critical initial step is achieving a transparent understanding of these intricate processes, where methodologies like process mining demonstrate significant value. This new model is architected to build agile, predictive, and increasingly autonomous supply chains that function as a true engine for sustainable growth.

Solving Core Business Challenges with Strategic Consulting

Supply chain consulting addresses the high-stakes, operational challenges that impact executive decision-making. For Germany’s industrial leaders, these challenges typically converge on four critical domains where missteps carry significant financial and market consequences. Each represents a direct threat to profitability but also a substantial opportunity for competitive differentiation when managed effectively.

A strategic consulting supply chain partnership provides the analytical clarity and execution capability required to transform these vulnerabilities into strengths. This involves mapping complex processes, identifying latent inefficiencies, and implementing robust, practical solutions that yield measurable results. The objective is to deliver a clear, actionable roadmap to operational excellence.

Achieving End-to-End Visibility and Control

A significant vulnerability for many German manufacturers is the lack of integrated visibility across global supplier networks. Attempting to track components across disparate, disconnected systems makes obtaining a real-time, accurate operational picture nearly impossible. This opacity creates substantial operational risk, leading to costly delays and reactive decision-making.

Consider an automotive firm sourcing microchips from multiple suppliers across Asia. Without a unified, single view, a production disruption at one supplier may not be identified until it is too late to mitigate effectively. The consequences include incurring premium costs for expedited shipping or, in a worst-case scenario, a complete production line shutdown.

Strategic consulting addresses this by designing and implementing data platforms that unify disparate information sources. These systems create a single source of truth, enabling leaders to track components from the factory floor to the final assembly line. Achieving this level of control is fundamental to a responsive and efficient operation. It transforms a deluge of raw data into sharp, actionable insights. Understanding the role of a consultant in business intelligence is central to this transformation.

Optimising Cost Structures for Greater Efficiency

Persistent margin pressure necessitates a rigorous approach to cost optimisation. However, indiscriminate budget reductions often prove counterproductive, compromising quality or damaging critical supplier relationships. The strategic approach involves surgically removing inefficiency without weakening the operational backbone of the supply chain. This requires analysis beyond obvious line items to uncover hidden costs embedded in daily processes.

For example, a machine manufacturer may experience significant capital drain from high inventory holding costs. The root cause is often not simply over-ordering but a systemic failure in demand forecasting accuracy.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

A targeted consulting engagement dissects these cost drivers with absolute precision. By analysing everything from warehouse space utilisation to payment terms with suppliers, consultants pinpoint opportunities to streamline operations and cut out waste, which feeds directly back to your bottom line. This could mean optimising transport routes, renegotiating supplier contracts, or implementing leaner inventory practices.

Building Robust Risk Mitigation and Resilience

In an environment of sustained geopolitical and market volatility, resilience is a core performance metric, not a buzzword. A supply chain architected solely for low cost is inherently fragile and susceptible to disruption. German enterprises must insulate their operations from external shocks, whether a sudden raw material shortage, a new trade barrier, or a natural disaster impacting a key supplier region.

The solution lies in proactive risk management, shifting from a reactive posture to one of anticipation and preparedness. Key strategies include:

- Supplier Diversification: Distributing sourcing to reduce dependency on a single entity or region, thereby mitigating geographical and political risk.

- Scenario Modelling: Utilising data to simulate the impact of potential disruptions and develop robust contingency plans in advance.

- Nearshoring or Reshoring: Strategically relocating production closer to end markets to reduce lead times and exposure to geopolitical friction.

These are not merely defensive measures; they construct a supply chain that can not only absorb a shock but also recover rapidly, protecting revenue and market share while competitors contend with disruptions.

Navigating Sustainability and Compliance Demands

Finally, regulatory and consumer pressure for sustainable and compliant supply chains continues to intensify. For German companies, legislation such as the Supply Chain Due Diligence Act (LkSG) imposes non-negotiable requirements. The central challenge is to meet these stringent transparency and ethical sourcing standards without compromising operational efficiency.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

This requires deep diligence and robust tracking systems to ensure every partner in the value chain adheres to required environmental, social, and governance (ESG) standards. An expert consulting partner helps implement the systems necessary to monitor compliance, manage documentation, and transform sustainability from a regulatory burden into a source of brand equity and customer trust.

Tapping into AI for Supply Chain Performance

For Germany’s industrial leaders, artificial intelligence is not a theoretical concept but a pragmatic tool capable of delivering immediate, tangible improvements to operations. The key is to move beyond industry buzzwords and focus on specific, high-value applications. A hands-on consulting supply chain partner can provide the necessary expertise to apply AI to solve concrete operational challenges.

The objective is not to replace human capital but to augment it. We focus on embedding intelligent systems into daily workflows, empowering your teams to make smarter, faster decisions based on predictive insights, not just historical data. The emphasis is on practical application and a direct line to bottom-line results.

AI-Powered Demand Forecasting

Traditional forecasting methodologies, heavily reliant on historical sales data, are often inadequate in the face of sudden market shifts or unforeseen global events. In contrast, AI-powered forecasting synthesises a wide array of inputs—including market trends, competitor activities, and macroeconomic signals—in real time. This provides a significantly more accurate and dynamic view of future demand.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

For a manufacturer, this capability closes the gap between an educated guess and data-driven certitude. Improved forecast accuracy enables optimised production schedules, reduced waste, and enhanced customer satisfaction, all while minimising the need for excessive safety stock. Furthermore, these systems are designed to learn continuously, refining their predictive accuracy with each new data point.

Intelligent Inventory Optimisation

Inventory management represents a classic optimisation challenge. Excessive inventory ties up working capital, while insufficient stock leads to stockouts, customer dissatisfaction, and lost revenue. AI-driven inventory optimisation identifies the optimal balance, not for a single product, but across thousands of SKUs simultaneously.

These systems analyse demand patterns, supplier lead times, and production capacity to recommend precise stocking levels.

- Free Up Capital: By reducing excess and obsolete stock, companies can unlock significant capital for reinvestment into growth initiatives.

- Prevent Shortages: AI anticipates demand spikes, ensuring critical components are available to prevent costly production stoppages.

- Automate Replenishment: The system can trigger reorders automatically based on predictive insights, reducing the manual workload on planning teams.

Consider an automotive supplier. An AI model could flag a potential semiconductor shortage weeks in advance. This foresight provides the necessary lead time to secure alternative suppliers, thereby averting an assembly line shutdown that could incur millions in daily losses.

Predictive Risk Modelling and Supply Continuity

Modern supply chains are exposed to a range of risks, from geopolitical tensions to extreme weather events. AI-powered risk models function as a global monitoring system, constantly scanning for threats before they can disrupt operations. This capability is foundational to building a truly resilient enterprise.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

By simulating the impact of various "what-if" scenarios, organisations can develop robust contingency plans. For instance, if a major shipping lane is identified as high-risk, the system can proactively recommend alternative routes or suppliers. This transforms risk management from a reactive, crisis-driven activity into a strategic, forward-looking discipline—a core component of modern AI strategies for logistics and supply chain mobility.

Strategic Procurement Automation

Procurement teams are often burdened with repetitive, administrative tasks such as processing purchase orders, tracking invoices, and managing routine supplier communications. AI can automate these manual workflows, freeing up expert personnel to focus on high-value activities like strategic sourcing, negotiating critical contracts, and cultivating stronger supplier relationships.

This is especially relevant in Germany’s supply chain consulting market, valued at approximately USD 1.4 billion and dominated by the manufacturing and automotive sectors. While traditional consulting focused on cost-cutting, the current imperative is IT & Digital Supply Chain Consulting, driven by the need for intelligent automation and analytics. Federal programmes like Manufacturing-X are accelerating this shift, creating a favourable environment for deploying production-ready AI systems.

Introducing the Co-Preneur Consulting Model

The traditional model for engaging a consulting supply chain firm is often suboptimal. An external team delivers a strategic analysis, collects a fee, and departs, leaving the client’s internal team with the challenge of implementation. This transactional approach creates a significant gap between strategic recommendation and operational reality.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

We advocate for a superior model built on true, integrated partnership. Our Co-Preneur model reframes the engagement entirely. We function not as external consultants, but as entrepreneurial partners embedded within your organisation, sharing accountability for achieving tangible results.

This approach aligns with the core values of the German Mittelstand, where trust, long-term perspective, and measurable outcomes are paramount. The focus is on collaboratively transforming strategic concepts into market-ready, operational solutions.

From External Advisor to Integrated Partner

The fundamental distinction of this model is the shift from a conventional client-vendor dynamic to a partnership of equals. We work with you, not for you. Our experts become an extension of your team, collaborating at every level.

This deep integration ensures that the solutions we develop are not only theoretically sound but also practical, culturally aligned, and tailored to your specific operational context.

Critically, this fosters genuine knowledge transfer. Our objective is not merely to complete a project but to build lasting capabilities within your organisation, empowering you to own and evolve these new systems independently. This hands-on methodology is central to our philosophy of Co-Preneurship in the AI era.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The following table contrasts the two approaches.

Traditional Consulting vs The Co Preneur Model

| Attribute | Traditional Consultant | Reruption Co-Preneur |

|---|---|---|

| Relationship | Client-Vendor (Transactional) | Integrated Partner (Collaborative) |

| Incentives | Tied to project delivery (reports, presentations) | Tied to P&L impact and business outcomes |

| Accountability | Limited to advisory scope | Shared ownership of results |

| Focus | Delivering recommendations | Implementing solutions and building capabilities |

| Knowledge Transfer | Passive (via documents) | Active (through hands-on collaboration) |

| Risk | Primarily borne by the client | Shared between client and partner |

The distinction is clear: one model is designed to sell advice, while the other is structured to build enterprise value collaboratively.

Tying Success to P&L Accountability

The most impactful feature of our model is the commitment to direct P&L accountability. In a standard consulting engagement, fees are tied to deliverables like reports. For us, success is contractually linked to the measurable financial and operational impact we generate together.

When your consulting partner has direct financial incentives aligned with your own, the engagement dynamic changes fundamentally. The focus shifts from proposing ideas to delivering outcomes that demonstrably improve your bottom line. This ensures every decision is rigorously evaluated against its real-world impact on profitability and growth.

Validating Strategy with Rapid Prototyping

Finally, we prioritise speed and validation. The German consulting market, now valued at €47.7 billion, indicates strong demand from SMEs for agile, results-oriented solutions. In industrial centres like Baden-Württemberg, companies require innovative partners who can de-risk new initiatives quickly, particularly as federal programmes now support such advisory costs. You can read more on the German consulting market and its growth shifts.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

Instead of protracted periods of theoretical analysis, we employ rapid prototyping. We build and test functional proofs-of-concept within weeks, not quarters.

This methodology offers three distinct advantages:

- De-risks Investment: You can validate a strategic concept with minimal upfront capital before committing to a full-scale implementation.

- Accelerates Learning: Tangible prototypes provide immediate, real-world feedback, enabling much faster iteration cycles.

- Builds Momentum: Demonstrating early, measurable success secures stakeholder buy-in and maintains project velocity.

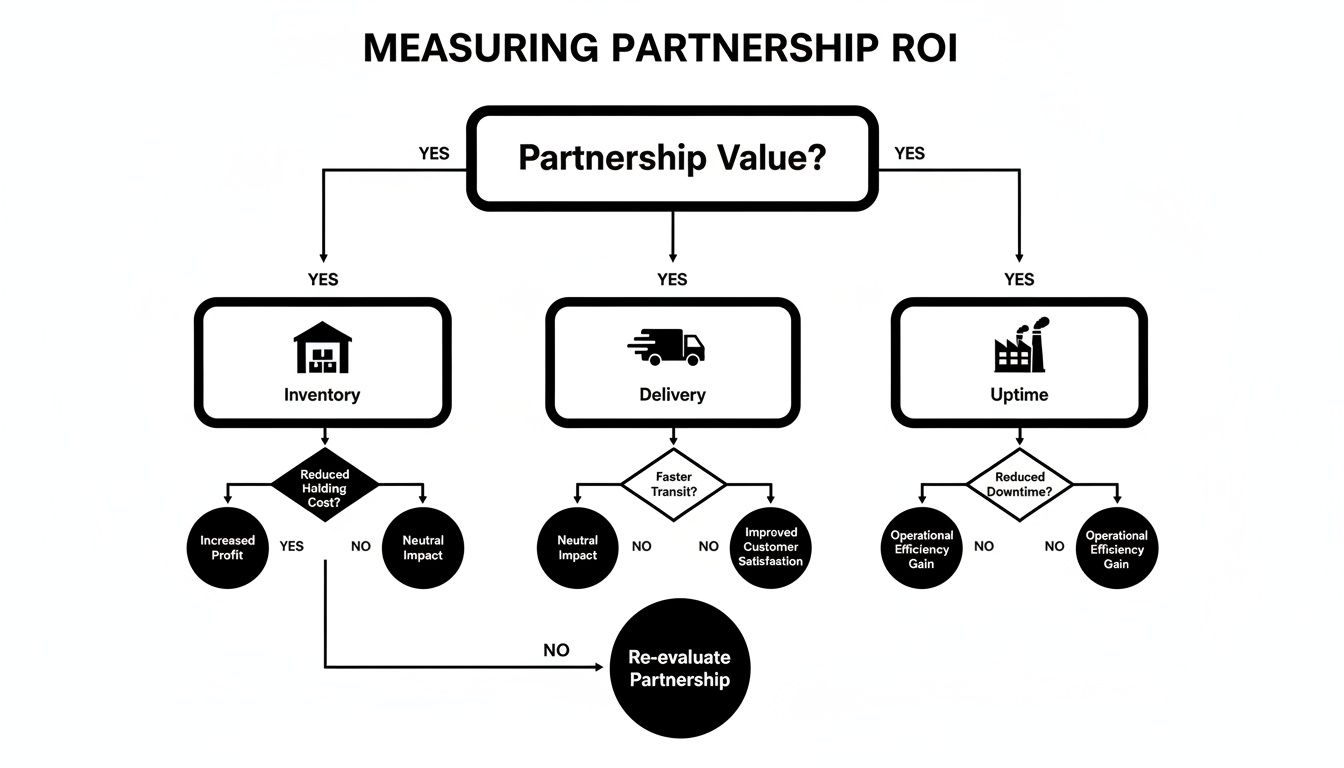

How to Measure the ROI of Your Consulting Partnership

Investing in a consulting supply chain partnership requires a clear, quantifiable return. For C-level executives, success is not measured in strategic presentations but in tangible improvements to the balance sheet and operational performance. A robust business case must move beyond abstract promises to focus on Key Performance Indicators (KPIs) that directly reflect financial health and operational strength.

Accountability begins with establishing a precise baseline at the start of the engagement. Progress is then tracked against specific, mutually agreed-upon targets. This creates a transparent framework for measuring the value delivered, ensuring every strategic initiative is directly linked to a measurable outcome. The focus remains squarely on verifiable improvements that strengthen the bottom line.

Quantifying Financial and Operational Gains

The most effective KPIs are those that directly link operational changes to financial impact. These metrics provide an unambiguous measure of value creation, simplifying the justification of investment and the demonstration of success to stakeholders.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

Key measurement areas include:

- Reduction in Inventory Holding Costs: A direct indicator of working capital efficiency. Utilising predictive analytics to optimise stock levels can significantly reduce the capital tied up in excess and obsolete inventory.

- Real-World Example: A mid-sized machinery manufacturer reduced its excess inventory by 22%, freeing up €4.5 million in working capital within nine months.

- Improvement in On-Time-In-Full (OTIF) Delivery: A critical measure of customer satisfaction and operational reliability. Higher OTIF rates reduce penalties, improve client retention, and strengthen brand reputation.

- Real-World Example: An automotive components supplier increased its OTIF rate from 87% to 96%, eliminating late-delivery fines and securing a major contract extension.

These examples illustrate how targeted operational enhancements translate into clear, demonstrable financial gains.

A true partnership is defined by shared accountability for results. The return on investment shouldn't be an afterthought—it should be the central pillar of the engagement, with success measured in euros saved, efficiencies gained, and risks avoided.

Tracking Efficiency and Cost Avoidance

Beyond direct capital gains, ROI is also realised through enhanced operational efficiency and strategic cost avoidance. These metrics demonstrate a partner’s ability to streamline processes and build a more resilient, cost-effective operation. Tracking these gains is essential for a complete assessment of the engagement's value.

- Decreased Expedited Freight Spend: This metric reflects improved planning and forecasting. The ability to anticipate disruptions and optimise logistics significantly reduces the need for costly last-minute shipping.

- Real-World Example: A consumer goods company reduced its expedited freight budget by 40% by implementing an AI-driven logistics model that proactively rerouted shipments around port congestion.

- Increased Production Uptime: This measures the impact of improved supply continuity on manufacturing operations. Reliable component delivery prevents costly line stoppages and maximises asset utilisation.

- Real-World Example: A specialty chemicals producer increased its plant uptime by 12% after its consulting partner helped diversify its raw material sourcing, preventing critical shortages.

By focusing on concrete KPIs like these, leaders can construct a powerful business case for any strategic consulting supply chain initiative. Of course, capturing this value depends on rapid implementation. To understand how production-ready AI systems can be delivered in weeks, not months, learn more about our 21-Day AI Delivery Framework and its pragmatic approach to rapid execution.

A Strategic Checklist for Choosing Your AI Supply Chain Partner

Selecting the right partner to integrate AI into your supply chain is a critical long-term decision. This is not about procuring a vendor; it is about establishing a strategic alliance. A structured evaluation process is necessary to distinguish true partners from those who offer proofs-of-concept without a viable path to production.

The best firms possess not only technical expertise but also a deep, pragmatic understanding of your market. This level of due diligence is essential across the supply chain—from selecting AI partners to using a customs broker selection guide to ensure compliant trade. The following checklist is designed to help you look beyond the sales presentation and identify a partner committed to building sustainable value within your organisation.

Assessing Technical Depth and Delivery Capability

A critical distinction exists between firms that build theoretical models and those that deploy production-ready systems. The objective is to implement solutions that generate tangible ROI, not to become mired in perpetual pilot projects.

Use these questions to assess their technical capabilities:

- Implementation Track Record: Can you provide specific examples of AI systems you have deployed in a live production environment for a client of our scale?

- System Ownership: What is your methodology for knowledge transfer? Will our team be fully enabled to operate, maintain, and enhance the solution post-engagement?

- Technology Stack: Is your approach technology-agnostic, selecting the optimal tools for the specific problem, or are you constrained by a single vendor ecosystem?

Evaluating Business Acumen and Strategic Alignment

A technically flawless solution that fails to address a core business problem provides no value. Your partner must be as fluent in the language of your P&L as they are in machine learning. They must comprehend the specific pressures and opportunities facing German industry.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The ultimate test of a consulting partnership isn’t the elegance of its strategy decks, but its direct, measurable contribution to the P&L. A true Co-Preneur partner shares this accountability, ensuring every technical decision is grounded in commercial reality.

To evaluate their business acumen, ask these questions:

- P&L Understanding: How, specifically, will your proposed solution impact our key financial metrics, such as inventory holding costs, operating expenses, or revenue?

- Risk-Sharing Models: Are you prepared to align your incentives with our success through performance-based or other risk-sharing engagement models?

- Industry Insight: What is your understanding of our specific market challenges, from regulatory requirements like the LkSG to the competitive dynamics of our sector?

This decision tree illustrates how to link a partnership’s value directly to core ROI drivers such as inventory, delivery, and uptime.

A framework like this ensures every initiative is evaluated based on its direct impact on financial performance. By asking these rigorous questions, you can select a consulting supply chain partner who will function as a true extension of your team—one committed to building resilient, intelligent operations that will secure your competitive advantage for the future.

Frequently Asked Questions

When considering the integration of AI into your supply chain, numerous questions naturally arise. Below are answers to the most common queries we receive from leadership teams.

How Quickly Can We Expect to See Results?

The traditional consulting model, which can take months to produce initial recommendations, is ill-suited to today's dynamic environment. We prioritise rapid prototyping, enabling us to deliver a functional proof-of-concept within weeks, not quarters. Consider, for example, an AI-powered demand forecast for a key product line.

This approach allows for early validation using your own data, building organisational momentum while de-risking larger-scale investment. Measurable improvements in pilot-group KPIs, such as reduced stockouts or enhanced forecast accuracy, are often achievable within the first three to six months.

Is Our Data Infrastructure Ready for AI?

This is a frequent and valid concern. Many organisations believe a pristine, centralised data warehouse is a prerequisite for any AI initiative. This is a misconception. An effective partner begins by defining the business problem and then identifies the minimum viable data required to solve it.

Our initial phase typically includes:

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

- Data Audit: A pragmatic assessment of your existing data assets to determine what is usable.

- Targeted Integration: Building focused data pipelines specifically for the initial problem statement.

- Pragmatic Solutions: Modern AI algorithms can often perform effectively even with imperfect or incomplete data. Perfection is not a prerequisite for progress.

The objective is to begin generating value immediately while concurrently developing a more robust, long-term data foundation. It is not necessary to wait for the completion of a multi-year IT project to realise benefits.

Will AI Replace Our Existing Supply Chain Team?

No. This is a significant misunderstanding of AI's role. AI is designed to augment your team's capabilities, not replace its members. Its function is to perform large-scale data analysis—a task that exceeds human capacity—thereby freeing up your personnel to focus on strategy and high-value decision-making.

Consider AI as a co-pilot for your supply chain managers. It provides predictive insights and automates repetitive tasks, allowing them to concentrate on strategic imperatives: negotiating with suppliers, planning for disruptions, and identifying new market opportunities.

The goal is to enhance your team's effectiveness, not render it obsolete. A successful partnership must include a robust enablement component, training your personnel to work effectively with these new systems to build sustainable, in-house expertise.

At Reruption GmbH, we do not merely advise; we act as your Co-Preneurs, sharing P&L accountability to transform your supply chain challenges into a distinct competitive advantage. Discover how we build and implement production-ready AI systems at https://www.reruption.com.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.