The industrial automation sector represents the central nervous system of modern production. It is the strategic integration of control systems, robotics, and intelligent software that enables industrial processes to operate with minimal direct human intervention. For German industry leaders, mastering this domain is no longer an incremental advantage—it is a foundational requirement for sustained global competitiveness.

The Strategic Imperative of Industrial Automation

In Germany's high-wage, high-skill economy, the demand for operational excellence is absolute. The industrial automation sector is the primary enabler of this objective. Its scope has evolved far beyond simple robotics on an assembly line into a sophisticated, interconnected ecosystem of intelligent systems.

For executives and managers, the strategic dialogue has fundamentally shifted from cost reduction to value creation. The focus is now on constructing shock-resistant supply chains, accelerating innovation cycles, and engineering production capabilities resilient enough to navigate global economic volatility. This is not merely an operational upgrade; it is a strategic pivot essential for long-term survival and growth.

A Sector Driven by Growth and Necessity

The quantitative evidence underscoring this strategic shift is compelling. The following snapshot of the market's trajectory provides a clear directional forecast.

German Industrial Automation Market Projections

| Metric | Current Value | Projected Value (2032) | Compound Annual Growth Rate (CAGR) |

|---|---|---|---|

| Market Size | USD 7.72 billion | USD 14.84 billion | 10.88% |

This data, derived from analysis by Data Bridge Market Research, reflects a national commitment to technological leadership. However, this growth is propelled not only by opportunity but also by significant operational pressures.

The persistent shortage of skilled labour, compounded by rising operational costs, presents a robust business case for automation. Intelligent systems do not merely replace human labour; they augment human expertise. This reallocation of talent allows your most valuable team members to focus on high-impact, strategic initiatives rather than repetitive tasks. The objective is a symbiotic relationship where technology amplifies human capital.

For German enterprises, automation is the key to unlocking the next frontier of productivity. It allows organisations to de-risk operations from labour market volatility and reallocate human capital toward innovation, strategy, and complex problem-solving—the very activities that define market leadership.

The Modern Automation Landscape

Today’s industrial automation encompasses a broad spectrum of applications, each engineered to address specific operational challenges. While the technologies may vary, the strategic objectives remain consistent: efficiency, quality, and resilience. Our guide on automation applications by industry offers a detailed exploration of sector-specific implementations.

Core focus areas include:

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

- Process Automation: Utilising control systems like SCADA and PLCs to manage continuous production processes, such as in chemical plants or food processing, where consistency and quality are paramount.

- Robotics and Material Handling: Deploying robotic arms and autonomous mobile robots (AMRs) for physically demanding or high-precision tasks, from automotive welding to warehouse logistics.

- Data Integration and Analytics: Connecting machinery through the Industrial Internet of Things (IIoT) to enable the collection of real-time data, facilitating a transition from reactive repairs to predictive maintenance and holistic performance optimisation.

Ultimately, maximising the value of the industrial automation sector requires a clear strategic vision that links every technological investment to core business objectives. The goal is to construct a more intelligent, agile, and competitive enterprise prepared for future challenges.

Understanding The Core Technologies Driving Modern Automation

Effective leadership within the industrial automation sector does not require deep technical expertise. Rather, it demands a strategic grasp of the core technologies sufficient to inform sound investment decisions and comprehend their business impact. A useful framework is to consider these technologies in two distinct yet convergent layers: the foundational control layer and the intelligent optimisation layer.

The Foundational Control Layer

At the core of nearly every automated facility are technologies engineered for reliable, real-time control. These are the workhorses that have powered industrial operations for decades.

Programmable Logic Controllers (PLCs) function as direct supervisors on the factory floor. They are ruggedized computers designed to execute specific, repetitive tasks with absolute precision, such as controlling a conveyor belt’s speed or ensuring a valve opens at a precise pressure. They are defined by their reliability.

Overseeing these supervisors is the Supervisory Control and Data Acquisition (SCADA) system. This serves as the central control room, providing a high-level, comprehensive view of the entire production line. Operators use SCADA to monitor processes, acquire data, and issue broad commands, ensuring operational harmony.

The Intelligent Optimisation Layer

While PLCs and SCADA provide essential control, the optimisation layer is where modern automation generates a significant competitive advantage. This layer shifts operations from being purely reactive to becoming predictive and adaptive.

The enabling technology is the Industrial Internet of Things (IIoT), which can be conceptualised as the facility's nervous system. It comprises numerous sensors collecting real-time data on variables such as machine temperature, vibration, and energy consumption. This continuous data stream is the raw input for intelligent decision-making.

By connecting previously isolated machines, IIoT dismantles data silos. This complete operational visibility is the fundamental prerequisite for moving beyond simple automation to genuine, data-driven optimisation.

This is where Artificial Intelligence (AI) and Machine Learning (ML) provide critical capabilities. If IIoT is the nervous system, AI is the brain. It processes the immense data volume from the IIoT network to identify patterns, predict outcomes, and recommend actions that are beyond human capacity to discern in real-time.

For instance, an ML model can analyse vibration data from a motor to predict a potential failure weeks in advance. This enables planned maintenance, averting costly, unplanned downtime. This is not theoretical; aerospace leaders already leverage ML to dramatically accelerate complex simulations. A relevant case study shows how Airbus used Machine Learning to speed up aerodynamic simulations by a factor of 120,000.

The Convergence Creating Smart Factories

The strategic power of today's industrial automation sector lies not in any single technology but in their convergence. A smart factory is created when the control and intelligence layers merge and function as a unified system.

- Data-Driven Control: IIoT sensors feed live data into an AI model. The model's insights are then translated directly into commands executed by PLCs on the factory floor, creating a self-optimising feedback loop.

- Predictive Operations: Instead of merely reacting to SCADA alarms, AI anticipates problems, enabling proactive adjustments that maintain peak performance and quality.

- Adaptive Processes: The entire system can learn. For example, it could automatically adjust production parameters in response to variations in raw material quality, ensuring final product consistency.

When integrated, these technologies create a system far greater than the sum of its parts. They transform a factory from a collection of isolated machines into a single, interconnected, and intelligent organism capable of adapting to challenges and seizing opportunities with unprecedented speed and precision. This integration is the foundation for the high-impact applications that follow.

The AI Advantage: Weaving Intelligent Automation into Your Operations

For senior leaders, the tangible value of technology manifests when it solves concrete business problems. Artificial Intelligence is no longer an abstract concept but a practical tool for achieving operational excellence today. Integrating AI transforms an organisation from being merely automated to being intelligent—creating systems that learn, adapt, and improve autonomously.

For German manufacturers, this translates technological potential into measurable gains. The focus must shift from technology adoption to the targeted resolution of high-impact operational challenges. This section provides a blueprint for that shift, framing AI solutions around the specific problems they address and the tangible results they deliver.

From Reactive Repairs to Predictive Maintenance

Asset downtime is a persistent adversary in capital-intensive operations. An unexpected equipment failure disrupts production schedules, incurs significant delays, and erodes profitability. The traditional model of reactive maintenance is fundamentally inefficient.

AI-powered predictive maintenance inverts this paradigm. By embedding IIoT sensors to monitor variables like temperature, vibration, and energy consumption, AI models can analyse historical and real-time data to detect subtle indicators of impending failure.

The system does not just trigger an alarm; it forecasts a specific fault weeks in advance and prescribes the necessary maintenance. This transforms maintenance from a cost centre into a strategic lever for improving Overall Equipment Effectiveness (OEE).

The measurable outcomes are a dramatic reduction in unplanned downtime, extended asset lifespan, and optimised maintenance schedules that minimise operational disruption.

Surpassing Human Limits in Quality Control

Achieving consistent quality at scale is a significant challenge. Manual inspection is slow, subjective, and susceptible to human error, particularly over long periods. Minor defects can lead to substantial material waste, customer returns, and reputational damage.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

Computer vision, a specialised field of AI, provides a decisive advantage. High-resolution cameras, powered by sophisticated AI algorithms, can inspect products on a production line with speed and accuracy unattainable by humans.

These systems identify microscopic cracks, subtle colour deviations, or minute assembly errors invisible to the naked eye. Trained on vast datasets of acceptable and defective products, the AI's judgment is objective and consistent, operating 24/7 without fatigue.

- Problem: High defect rates and inconsistent quality from manual inspections.

- AI Solution: AI-driven computer vision systems for automated, continuous quality control.

- Measurable Outcome: A significant decrease in defect rates, reduced material waste, and a consistently higher-quality final product.

Practical applications, detailed in resources on machine learning in manufacturing, are proving transformative, reducing costs while simultaneously increasing output.

Optimising Complex Supply Chain Logistics

Modern supply chains are intricate networks of countless variables. Managing inventory, forecasting demand fluctuations, and optimising transport routes are exceedingly complex tasks. Minor inaccuracies in traditional, history-based planning methods can lead to substantial cost escalations.

AI models can process vast and diverse datasets—including sales figures, weather forecasts, port congestion data, and supplier performance metrics—to generate highly accurate demand forecasts and logistics plans. This enables a shift from a rigid supply chain to a dynamic, responsive one.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

For example, an AI system can instantly re-route a shipment to avoid a port delay or adjust inventory levels across warehouses based on real-time sales data. Making such decisions at speed and scale is impossible with conventional tools. These concepts are now being implemented using internal large language models; you can explore the architecture of an internal LLM engine for cross-functional automation in our dedicated guide.

This intelligent approach leads directly to lower inventory holding costs, reduced shipping expenses, and improved on-time delivery rates, ultimately resulting in higher customer satisfaction and a more resilient operational backbone.

Navigating The German Automation and Regulatory Ecosystem

Successful implementation of intelligent automation in Germany requires more than technological proficiency. It demands a sophisticated understanding of the local market and a rigorous adherence to its stringent regulatory framework. For decision-makers, this necessitates selecting a partner with both deep engineering expertise and a nuanced appreciation of the unique challenges and expectations of German industry.

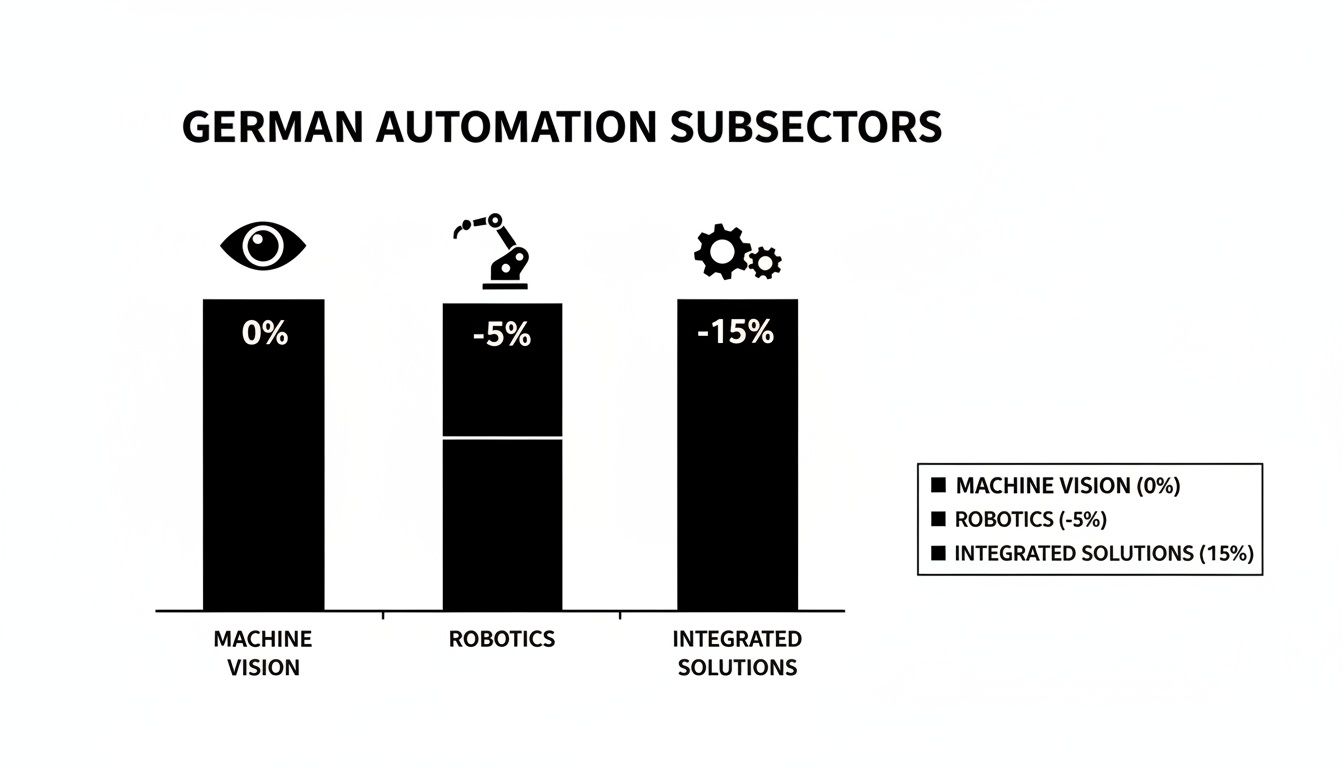

The German industrial automation sector is a mature market. While dominated by global leaders like Siemens and Bosch, its core strength lies in the Mittelstand—a vast ecosystem of highly specialised small and medium-sized enterprises (SMEs). This creates an environment that is both highly innovative and one where trust and proven reliability are paramount.

Success in this market requires strategic foresight. While market cycles will create fluctuations, the fundamental drivers for automation remain constant. The imperative is one of strategic investment, timed to secure long-term competitive advantages.

The Bedrock of Compliance: Data Governance and Security

For German companies, data is not merely an asset; it is a fiduciary responsibility. This principle governs all technology decisions, particularly for automation systems that generate vast quantities of sensitive operational data. Here, compliance is not a procedural formality but an absolute foundation.

Two frameworks are particularly influential:

- GDPR (General Data Protection Regulation): While often associated with consumer data, its core principles—data minimisation, purpose limitation, and security by design—are equally applicable to industrial data involving employees.

- TISAX (Trusted Information Security Assessment Exchange): Originating in the automotive sector, TISAX has become the de facto standard for information security across the manufacturing supply chain, mandating strict, verifiable controls over data management.

These regulations foster a strong preference for secure, on-premises data processing. While cloud adoption is increasing, on-premise platforms remain prevalent. This is a pragmatic response to rising labour costs and skilled worker shortages, combined with an unwavering commitment to data sovereignty.

In the German industrial context, trust is built on security. A failure in data governance is not a technical misstep—it is a commercial disqualifier. Any credible partner must demonstrate an unconditional, day-one commitment to secure and compliant data handling.

Preparing for Future Regulatory Shifts

The regulatory landscape is dynamic. New regulations continually emerge, reshaping how digital products and AI systems are developed and deployed in the industrial domain. Proactive engagement with these changes is essential to mitigate future risks.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

A significant development is the EU's increasing focus on the security of digital products. The Cyber Resilience Act is poised to introduce mandatory cybersecurity standards for nearly all products with a digital component, from simple IIoT sensors to complex factory control systems.

Understanding these requirements now is critical. An expert partner can help navigate this evolving landscape, ensuring that automation solutions implemented today remain compliant in the future. This foresight is non-negotiable for any major investment. We detail how to ensure projects meet these stringent standards in our overview of AI security and compliance for industrial automation.

Ultimately, selecting a collaborator fluent in both technology and the nuances of German regulation is the single most critical step to de-risking your automation journey and unlocking its full strategic potential.

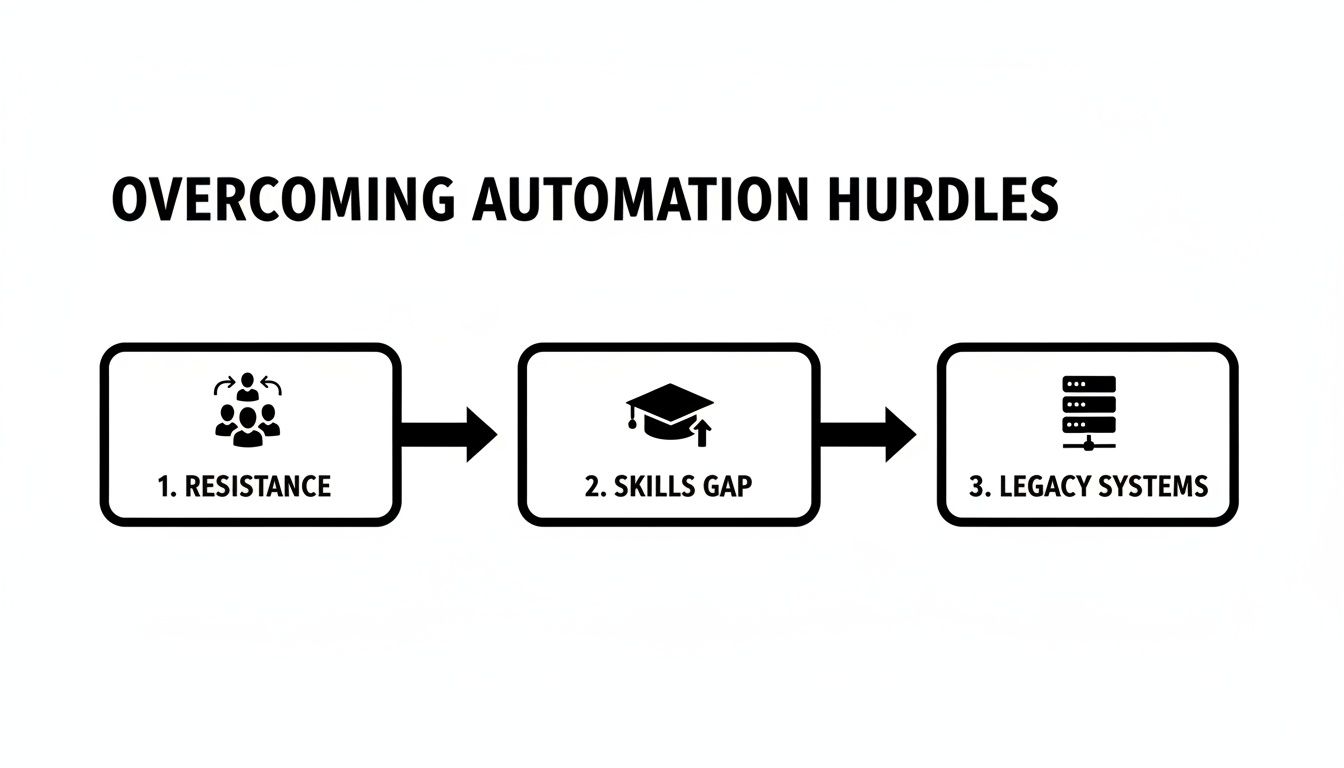

Overcoming Common Adoption Challenges In Large Organisations

Integrating intelligent automation into a large organisation is rarely a purely technical exercise. While significant time can be spent debating technology platforms, the most formidable obstacles are typically human and organisational. For leaders in large German enterprises, successfully navigating these challenges differentiates a short-lived pilot project from a genuine operational transformation.

The substantive work begins long before the first line of code is written. It starts with a clear-eyed assessment of the cultural and structural roadblocks. Overcoming these requires a deliberate strategy focused on building momentum, demonstrating early value, and achieving organisational alignment.

Addressing Resistance and Building Internal Alignment

The most significant challenge is often internal resistance. Apprehension among shop-floor personnel regarding job security and scepticism from departmental managers about disrupting established routines are natural human reactions to change. Proactive management of these concerns is essential.

A new narrative must be established. Automation should be positioned not as a tool for replacement but as one for augmentation. It is a powerful instrument that liberates teams from monotonous, repetitive tasks, enabling them to focus on complex problem-solving and innovation—activities where human expertise is indispensable.

This requires a clear, consistent message driven from senior leadership. Crucially, key stakeholders and end-users must be involved from the project's inception. Granting them a sense of ownership can transform sceptics into advocates.

A phased rollout is the most effective implementation strategy. Avoid a high-risk, "big-bang" overhaul. Instead, select a single, well-defined problem and execute a rapid proof-of-concept (PoC). Achieving a tangible, measurable win—however small—is the most potent method for securing the buy-in required for broader initiatives.

Bridging the Internal Skills Gap

The second major impediment is the skills gap. While existing teams possess invaluable institutional knowledge, they may lack the specific competencies needed to manage and maintain new AI-driven systems. Attempting to hire for these skills is often slow and expensive; upskilling the current workforce is the more sustainable strategy.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

A targeted training program is required. The objective is not to convert machine operators into data scientists but to equip all personnel with practical, role-specific skills that build both confidence and competence.

- For Operators and Technicians: Focus on hands-on training for new equipment operation and interpretation of data dashboards.

- For Middle Management: Provide training on leading AI-augmented teams and using data to make more informed, rapid operational decisions.

- For IT and Engineering: Offer advanced training on system integration, data security, and governance to ensure smooth and secure operations. Our article on system engineering in modern IT provides further detail on these complexities.

Integrating New Systems with Legacy Infrastructure

Few companies have the luxury of starting with a clean slate. Most operate within a complex environment of modern automation tools and decades-old legacy systems. This technical debt creates significant integration challenges, data silos, and potential security vulnerabilities.

Successful integration requires a methodical, interoperability-first approach. This may involve using middleware to act as a translator between old and new systems or adopting a modular strategy that gradually phases out legacy components rather than attempting a complete overhaul.

This situation reflects the current German market. Despite economic headwinds affecting the robotics and automation industry, adoption rates remain high. Leaders recognise that automation is essential for competitiveness, driving modernisation efforts even when technical challenges are substantial. Further insights are available in the U.S. government's analysis of Germany's advanced manufacturing landscape on trade.gov.

Your Practical Roadmap For AI-Driven Automation Adoption

Integrating AI into an industrial automation environment is not a protracted academic exercise. It demands a sharp, agile framework that delivers results quickly. Traditional, slow-moving consulting models are no longer sufficient. Leaders require a de-risked, entrepreneurial approach focused on speed and tangible outcomes.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

This roadmap provides such a framework, breaking the complex journey into four clear, actionable stages. It is a model built on shared accountability, designed to move from concept to production-ready innovation with speed and precision.

Phase 1: Strategic Use Case Discovery

The process begins not with technology but with business value. The initial step is a collaborative deep dive to identify high-impact use cases where AI can resolve a persistent operational challenge or unlock a new revenue stream.

This is more than a brainstorming session; it involves constructing a rigorous business case, quantifying the potential return on investment, and defining clear Key Performance Indicators (KPIs) from the outset. The objective is to establish a solid, data-backed rationale for the project, ensuring technical work is perfectly aligned with strategic goals.

Phase 2: Rapid Prototyping And Validation

With a solid business case, the focus shifts to speed. The goal is to build a functional prototype—a minimum viable product (MVP)—in days or weeks, not months. This phase is dedicated to testing the core hypothesis with real data and demonstrating tangible proof that the concept is viable.

This agile approach serves as a powerful de-risking mechanism. By validating the idea early with a working model, you can quickly identify what works and what does not, allowing for rapid iteration or a swift pivot without committing significant resources to a flawed concept.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The primary advantage of this phase is velocity. Delivering a demonstrable proof-of-concept to stakeholders quickly is the single most effective way to overcome internal scepticism, build momentum, and secure the necessary buy-in to scale the initiative.

The diagram below illustrates typical hurdles this agile process is designed to overcome.

This process directly addresses internal resistance, skills gaps, and legacy system roadblocks by proving value before requiring a major commitment.

Phase 3: Secure Engineering For Production

Once the prototype's value is validated, engineering efforts shift to building a robust, secure, and compliant system ready for a production environment. This entails developing scalable data pipelines, ensuring seamless integration with existing infrastructure, and hardening the entire system against security threats.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

For German enterprises, this stage is mission-critical. It demands an uncompromising focus on data governance and full compliance with standards such as TISAX and GDPR. The final solution must be not only powerful but also impeccably secure and trustworthy.

Phase 4: Team Enablement For Long-Term Success

The final component is ensuring the innovation is sustainable. Technology deployment alone is insufficient; the organisation must be empowered to own and operate the new system effectively. This requires hands-on team training, comprehensive knowledge transfer, and the establishment of clear operational processes.

This co-preneurial approach ensures that internal teams are active partners in the process, not passive recipients. By enabling your people, you empower your enterprise to innovate from within, securing a lasting competitive advantage in the industrial automation sector.

Your Questions Answered: Getting Started With Industrial Automation

You have seen the potential and understand the strategic rationale. However, translating a high-level strategy into a tangible implementation on the factory floor raises practical questions.

This section addresses common challenges leaders face concerning investment, integration, and results.

How Do We Actually Budget For Our First Automation Project?

Viewing the initial investment as a single capital expense is a common mistake. The cost of hardware or software licences is only one component. A more strategic approach is to evaluate the Total Cost of Ownership (TCO) against the projected Return on Investment (ROI).

A comprehensive budget should encompass three key areas:

- Technology Acquisition: The direct cost of robots, sensors, control systems, and software licences for AI or analytics platforms.

- Integration and Engineering: Often the largest component, this covers the specialised work required to integrate new systems with existing legacy equipment. This is not a plug-and-play process.

- Team Enablement: Training should be considered a direct investment in project success, not an expense. Budgeting for upskilling builds long-term internal capability and reduces long-term external dependency.

The recommended approach is to begin with a well-defined pilot project. Select a high-impact area, demonstrate value quickly, and use that success to build a robust business case for a wider rollout. This significantly simplifies securing subsequent, larger budget approvals.

Can We Really Connect New Automation To Our Old Systems?

Yes, and this is a critical success factor for most projects. A "rip and replace" strategy is impractical for established manufacturers.

A modular approach is the solution. Modern capabilities can be introduced without decommissioning trusted infrastructure. This is typically achieved using middleware and APIs (Application Programming Interfaces), which act as universal translators, enabling new AI platforms to communicate effectively with older control systems like PLCs.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

The objective is not to replace everything, but to create a unified data stream without disrupting daily operations.

Successful integration is a strategic challenge, not just a technical one. It requires a partner who understands both modern AI architecture and the realities of industrial technology. The goal is a seamless flow of data without compromising the stability and security you depend on.

What’s A Realistic Way To Measure The ROI?

Measuring the return on an automation investment extends far beyond calculating reduced labour costs. A comprehensive business case requires a balanced scorecard that reflects deep operational improvements.

Key performance indicators that truly matter include:

- Overall Equipment Effectiveness (OEE): The gold standard for measuring manufacturing productivity, OEE is a composite metric of availability, performance, and quality. AI-driven predictive maintenance can dramatically improve this figure.

- Reduced Defect Rates: Quantify the cost of poor quality, including material waste and warranty claims. Computer vision and other AI tools can demonstrate a clear financial impact.

- Reduced Unplanned Downtime: Every hour of lost production has a calculable cost. Track how predictive analytics reduces these expensive, unforeseen interruptions.

Ultimately, the most compelling ROI calculation is one that draws a direct line from the technology investment to primary business objectives, such as increased market share, a more resilient supply chain, or a sustainable competitive advantage.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

Ready to transform concepts into a competitive edge? Reruption GmbH operates as your Co-Preneur, rapidly converting AI-driven ideas into production-ready innovations. Find out how we de-risk and deliver automation projects that create lasting value.