Strategic automation involves the intelligent application of systems to streamline operations, from the factory floor to the finance department. This is not merely about automating isolated tasks; it is about architecting an intelligent operational backbone to build resilience, efficiency, and market leadership. For German enterprises, this is a critical strategic imperative, not an incremental technology upgrade.

The Strategic Case for Industrial Automation

In the face of persistent economic headwinds and intense global competition, German companies must look beyond marginal improvements. Intelligent automation offers a clear opportunity to re-engineer value chains, securing a sustainable competitive advantage. It is the engine for creating more robust, efficient, and innovative enterprises capable of navigating market volatility.

This initiative is not about workforce reduction. It is about talent elevation. Automation liberates skilled teams from repetitive, low-value work, enabling them to focus on complex problem-solving and innovation—the very activities that drive long-term growth. By integrating intelligent systems, companies can achieve a level of operational excellence unattainable through manual processes alone.

Navigating a Complex Market

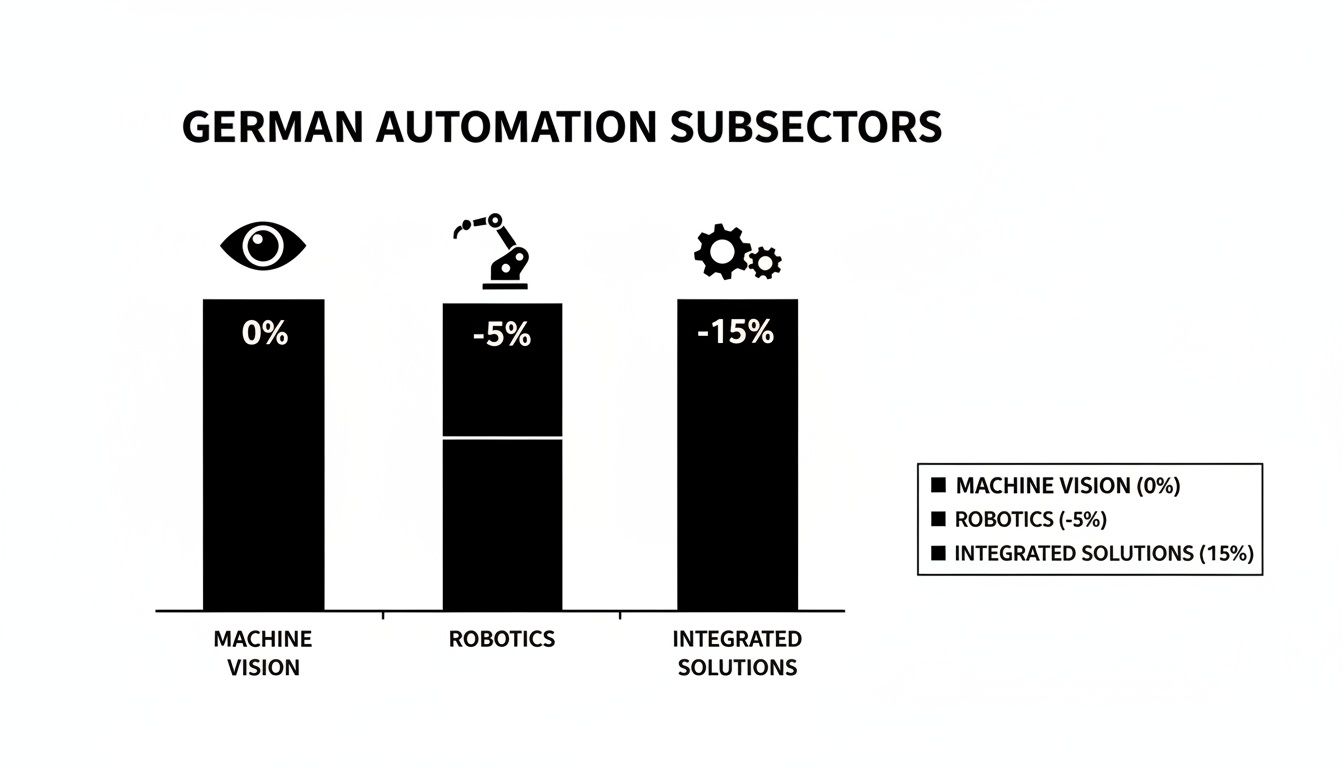

The German automation market is undergoing a period of structural change. The latest VDMA forecasts for 2025 present a complex outlook, with significant divergence across subsectors. While machine vision is projected to maintain stable revenues around €3.1 billion, robotics are anticipated to decline by approximately -5%. The most pronounced shift is in integrated automation solutions, which face a potential -15% contraction.

This data underscores the cyclical nature of large-scale capital projects. It signals a clear need for German enterprises to diversify technology investments and maintain a strategic focus on process innovation to sustain forward momentum.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

For German leadership, the operative question is no longer whether to automate, but how to implement automation to achieve specific strategic objectives. It is a direct response to the need for enhanced cost management, supply chain stability, and an increased capacity for innovation.

Achieving this strategic alignment is the foundation of any successful digital transformation. When leaders view automation through this lens, they ensure every technology investment is directly linked to a core business objective. For a detailed examination of this strategic methodology, our strategic guide for German executives on corporate digitalisation provides a comprehensive resource.

The following sections will analyse automation by industry, offering a clear framework for your organisation.

How Automation Creates Value Across Key Sectors

Automation is not a monolithic solution. Its application and value proposition differ significantly across industries. For German enterprises, understanding these nuances is critical to identifying high-impact opportunities. A successful strategy in automotive manufacturing, for example, is not directly transferable to optimising a financial services firm.

The key is to move beyond a generic concept of "automation by industry" and analyse its function within your specific operational context. Each sector has unique processes, regulatory frameworks, and value drivers that dictate how automation should be deployed for maximum effect.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

This sector-specific approach enables leadership to identify precise use cases, measure performance with relevant Key Performance Indicators (KPIs), and align technology investments directly with strategic business outcomes. Let us examine what this entails across Germany's core industries.

Automotive Precision Reimagined

Germany's automotive sector, a global benchmark for engineering excellence, has been a pioneer in automation for decades. Initial applications involved robotic arms on assembly lines, but today's automation is far more sophisticated, encompassing the entire value chain from design to after-sales support.

Here, intelligent automation is essential for managing immense complexity. It addresses challenges such as just-in-time supply chains, stringent quality control, and the systemic shift towards electric and autonomous vehicles.

- Predictive Maintenance: AI algorithms analyse data from production machinery to forecast equipment failure before it occurs. This strategic intervention drastically reduces unplanned downtime, a critical factor when every minute of production carries significant financial weight. The primary KPI is Overall Equipment Effectiveness (OEE).

- Automated Quality Control: High-resolution cameras and machine vision systems inspect components with a speed and accuracy that surpasses human capability. This ensures adherence to Germany's high quality standards, reducing defect rates and improving First Pass Yield (FPY).

- Supply Chain Optimisation: Automation platforms orchestrate the complex flow of components from thousands of suppliers. By forecasting demand and optimising logistics in real-time, manufacturers minimise inventory costs and prevent production stoppages, directly impacting Days of Inventory and On-Time Delivery rates.

Manufacturing Efficiency Redefined

Beyond the automotive sector, Germany’s broader manufacturing base—the renowned Mittelstand—leverages automation to maintain its competitive edge. The focus here is often on enhancing production line flexibility, ensuring worker safety, and enabling the delivery of customised products at scale.

In this context, automation acts as a force multiplier for skilled labour. It assumes physically demanding, repetitive, or hazardous tasks, freeing expert technicians to focus on configuration, oversight, and process improvement. To understand the diversity of these applications, it is valuable to explore various industry-specific automation solutions.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

A leading European machine tool manufacturer integrated a team of collaborative robots (cobots) to work alongside human operators. The cobots managed the heavy lifting and precise positioning of metal components, while operators focused on final quality assurance and complex assembly. The outcome was a 20% increase in productivity and a significant reduction in workplace injuries.

Automation Impact Matrix Across Key German Industries

For a holistic perspective, this matrix provides a snapshot of automation applications across Germany's core sectors, linking specific initiatives to tangible business outcomes.

| Industry Sector | Primary Automation Application | Key Performance Indicator (KPI) Impacted | Core Business Value |

|---|---|---|---|

| Automotive | Predictive Maintenance on Assembly Lines | Overall Equipment Effectiveness (OEE) | Reduced Downtime, Increased Output |

| Manufacturing | Collaborative Robots (Cobots) for Assembly | Labour Productivity, Injury Rates | Enhanced Worker Safety & Efficiency |

| Financial Services | AI-Powered Fraud Detection | Fraud Detection Rate, False Positives | Risk Mitigation, Asset Protection |

| E-commerce | Autonomous Mobile Robots (AMRs) in Warehouses | Order Fulfilment Cycle Time | Faster Delivery, Scalable Operations |

| Technology | Automated Software Testing (CI/CD) | Bug Detection Rate, Release Frequency | Accelerated Development, Better Quality |

This matrix demonstrates that successful automation is not about the technology itself, but about its precise application to solve high-value problems within each industry's unique context.

Financial Services Security and Speed

In finance and insurance, automation's value is primarily measured by its ability to reduce risk, ensure regulatory compliance, and enhance customer experience. The "products" are digital and the processes are data-intensive, making them ideal candidates for software automation technologies like Robotic Process Automation (RPA) and AI.

- Fraud Detection: AI systems analyse millions of transactions in real-time, identifying anomalous patterns indicative of fraudulent activity. This is an essential tool for protecting both the institution and its clients, directly improving the Fraud Detection Rate and reducing financial losses.

- Automated Underwriting: In the insurance sector, algorithms can analyse vast datasets to assess risk and determine policy premiums far more rapidly than human underwriters. This accelerates the application process, reducing the Customer Acquisition Cost (CAC) and improving client satisfaction.

- Regulatory Reporting (RegTech): Automation is indispensable for navigating complex regulatory frameworks such as BaFin requirements and DSGVO/GDPR. RPA bots can extract data from disparate systems and compile mandatory reports with perfect accuracy, mitigating the risk of costly compliance failures.

The German automation sector itself is not immune to market fluctuations. The data below illustrates the performance variability across its key subsectors.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

This downturn, particularly in integrated solutions and robotics, indicates a heavy dependence on the investment cycles of the automotive industry—a clear structural vulnerability.

Germany’s robotics and automation revenue experienced a sharp cyclical downturn in 2024–2025, exposing these structural weaknesses. After reaching a peak of nearly €16.0 billion in 2023, revenues declined by approximately 6% in 2024 and were projected to fall another 9–10% in 2025. This was driven by weakening domestic demand, with orders from the German market falling by around 16%. Analysts identify an over-reliance on the automotive sector and increasing competition as the primary causes.

E-Commerce Operations at Scale

For Germany's expanding e-commerce market, automation is the engine that drives the entire customer experience. The strategic objectives are to manage immense order volumes, achieve rapid delivery times, and offer a personalised shopping journey at a viable cost structure.

It is the automation within warehouses and back-office functions that makes two-day shipping and seamless returns a commercial reality.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

- Robotic Fulfilment: Autonomous mobile robots (AMRs) navigate large warehouses to pick and transport items for packing. This significantly increases the speed and accuracy of order fulfilment, directly improving the Order Fulfilment Cycle Time and reducing labour costs.

- Personalised Marketing: AI algorithms analyse customer browsing and purchasing data to generate intelligent, personalised product recommendations and marketing communications. This enhances engagement and conversion rates, increasing the Customer Lifetime Value (CLV).

- Intelligent Customer Service: AI-powered chatbots operate 24/7 to address common customer inquiries, such as order tracking and return initiation. This frees human agents to manage more complex issues, improving the First Contact Resolution Rate and overall customer satisfaction.

Understanding Your Core Automation Toolkit

Effective deployment of automation requires a clear understanding of the core technologies. These are not interchangeable buzzwords but distinct tools, each engineered for a specific function.

A helpful analogy is to view them as different specialists on a high-performance team. This clarity is crucial for senior leaders. It enables you to move beyond technical jargon and engage in meaningful discussions about investment, resource allocation, and strategy, ensuring that technology serves the business—not the other way around.

Robotic Process Automation: The Digital Workforce

Consider Robotic Process Automation (RPA) as your digital workforce. These are software "bots" programmed to emulate human actions for repetitive, rule-based tasks. They function as tireless administrators, operating 24/7 to execute predictable digital processes without error.

RPA is most effective for processes that adhere to clear "if-then" logic. For instance, an RPA bot can open an email, extract data from an invoice, input that data into an ERP system, and then archive the email. It performs these actions with perfect accuracy and speed, liberating your team from monotonous work.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

The primary value is a significant increase in operational efficiency and a sharp reduction in errors. It is often the first layer of automation for many organisations—a solid starting point for addressing high-volume, stable processes where the rules are well-defined.

RPA automates a process. It follows a pre-defined script, much like an actor in a play. While exceptionally efficient, it cannot improvise or learn. Its strength lies in the flawless execution of a pre-defined sequence.

Successful RPA implementation delivers quick wins and builds the organisational confidence necessary to adopt more advanced technologies.

Artificial Intelligence: The Digital Brain

If RPA is the workforce, then Artificial Intelligence (AI) and its key subfield, Machine Learning (ML), constitute the digital brain. While RPA follows explicit instructions, AI is designed to simulate human intelligence. It can analyse complex data, identify patterns, make predictions, and learn from experience.

This capability enables a more strategic level of automation. AI does not merely execute tasks; it makes judgements. It is the engine that powers predictive maintenance on a factory floor, with an algorithm analysing sensor data to flag potential equipment failure before it occurs. It also drives sophisticated fraud detection systems in finance, identifying subtle anomalies in transaction patterns that a human would likely miss.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

AI's function is to manage ambiguity and complexity. Key applications include:

- Natural Language Processing (NLP): Enables systems to understand and respond to human language, which is the technology behind intelligent chatbots and the analysis of unstructured text in documents.

- Computer Vision: Gives machines the ability to "see" and interpret visual information—a critical component for automated quality control in manufacturing.

- Predictive Analytics: Uses historical data to forecast future outcomes, from customer demand to supply chain disruptions.

The business value of AI derives from its ability to uncover insights and automate complex decisions, providing both an efficiency gain and a strategic advantage. For any organisation committed to innovation, exploring the possibilities of industrial automation and robotics is a non-negotiable next step.

The Internet of Things: The Digital Nervous System

Finally, the Internet of Things (IoT) functions as the digital nervous system, connecting the physical and digital worlds. IoT is a network of physical objects—machines, vehicles, appliances—embedded with sensors and software that allow them to connect and exchange data over the internet.

These IoT devices are the data collectors. They provide the real-time information that both RPA bots and AI algorithms require to perform their functions effectively. In a smart factory, for instance, IoT sensors on an assembly line constantly monitor variables like temperature, vibration, and output.

This continuous data stream is fed into an AI system, which might identify a potential quality issue or an impending machine failure. An automated alert could then trigger an RPA bot to create a maintenance ticket in your enterprise system.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

This synergy is where the true power of automation is realised. IoT provides the senses, AI provides the brain, and RPA provides the hands to execute actions. Understanding how these three components interact is key to designing powerful, end-to-end automation solutions that deliver tangible business value, regardless of your industry.

Choosing the Right Implementation Model for Your Enterprise

Selecting the appropriate technology is only half the challenge. For an automation initiative to generate enterprise-wide value, it requires a supporting organisational structure. A common error is to impose a one-size-fits-all model on a company, disregarding its unique culture and operational realities.

The critical question for leadership is not just what to automate, but how to organise the people and processes to enable it. Establishing the right implementation model from the outset is a foundational decision that will dictate the speed, success, and sustainability of your entire automation programme.

The Centralised Centre of Excellence

One of the most structured approaches is the establishment of a centralised Centre of Excellence (CoE). This can be conceptualised as a central command for all automation initiatives within the company. This model prioritises standardisation, governance, and control.

A CoE is typically staffed by a cross-functional team of experts in process analysis, automation development, and project management. Their mandate is to define best practices, develop reusable automation components, and ensure every project aligns with overarching business objectives. This structure is particularly beneficial for organisations where risk management and compliance are paramount, such as in financial services or pharmaceuticals.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

The potential drawback is that a centralised model can become a bottleneck, impeding the pace of innovation within business units. It requires a significant upfront investment in talent and infrastructure, but the long-term payoff is stability and scalable efficiency.

The purpose of a Centre of Excellence is to build the capability once and deploy it many times. It establishes a single source of truth for automation governance, preventing a chaotic proliferation of fragmented, inefficient, and insecure solutions.

This controlled approach is ideal for deploying enterprise-wide platforms where consistency is critical.

The Decentralised Federated Model

At the opposite end of the spectrum is the decentralised or federated model. This approach empowers individual business units or departments to manage their own automation initiatives. Central IT or leadership may provide the tools and a lightweight governance framework, but the teams closest to the processes are responsible for identifying, developing, and managing their own automations.

This model fosters agility and accelerates innovation. Business units can address their specific operational challenges without waiting for approval from a central team. It is an excellent fit for diverse, fast-moving organisations where different divisions have highly distinct needs. For corporate cultures that value autonomy and an entrepreneurial mindset, this model feels natural.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

The primary risk is a lack of coordination, which can lead to duplicated effort, inconsistent quality, and security vulnerabilities. For this model to succeed, it is imperative to equip business-unit teams with the necessary skills and establish clear, non-restrictive guardrails.

The Hybrid Approach: A Balanced Framework

For many large German enterprises, the optimal solution lies between these two extremes. The hybrid model combines the best elements of both, striking a balance between central governance and business-unit agility.

In this configuration, a lean central CoE sets the overall strategy, defines security standards, and manages the core automation platform. However, the actual development and implementation occur within "satellite" automation teams embedded directly within the business units. This creates a powerful synergy:

- Central Governance: Ensures that all automation projects adhere to the company's security and compliance protocols.

- Local Execution: Allows business units to develop solutions tailored to their specific needs, which fosters ownership and accelerates the delivery of results.

This balanced framework cultivates a collaborative culture. Best practices are shared across the organisation, but innovation is not stifled by bureaucracy. It is a pragmatic approach to scaling automation effectively while managing risks. A robust AI strategy for industrial automation and robotics is essential for determining which projects are best managed centrally versus locally.

Ongoing investment in automation underscores its strategic importance. In Germany, new industrial robot installations increased by approximately 7% in 2023, continuing a growth trend. While the market has experienced cyclical volatility, particularly in sectors like automotive, the long-term outlook remains strong. Analysts forecast a compound annual growth rate of roughly 7.4% for the German industrial automation market from 2025–2030. This highlights why a resilient implementation model is so critical to capturing future growth.

Navigating the Governance and Security Landscape

Integrating automation into core business operations is not merely a technical challenge; it introduces new dimensions of regulatory and risk considerations. For any German company, addressing these issues is not just good practice—it is a strategic necessity.

A robust governance framework must be established from day one. This is not about impeding progress. It is about ensuring that innovation does not inadvertently create significant security vulnerabilities or compliance failures.

This involves asking critical questions before they become crises. How will automated systems handle sensitive customer data? Who is accountable if an automated process fails or produces an incorrect outcome? What is the contingency plan if a system is compromised? Neglecting these fundamentals can lead to severe operational, financial, and reputational damage.

Fortifying Against Automation-Specific Threats

Each automated process expands your company's attack surface. Your cybersecurity strategy must evolve beyond traditional network defence to account for vulnerabilities unique to automation platforms.

These are not conventional threats. A compromised RPA bot could be used to exfiltrate financial data or disrupt supply chain operations with alarming speed. AI models are also vulnerable to data poisoning, where malicious actors introduce manipulated data to corrupt their decision-making processes.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

To mitigate these risks, security must be integrated into the automation lifecycle from the outset, not added as an afterthought. Key areas of focus include:

- Access Control: Implement rigorous identity and access management for every automated agent, whether software or hardware. They should have access only to the data and systems absolutely necessary for their function.

- Continuous Monitoring: Utilise advanced tools to monitor automated workflows in real-time. You must be able to detect anomalous behaviour that could indicate a breach or system malfunction.

- Secure Development: Build automation solutions with a security-first methodology. This includes mandatory code reviews and vulnerability testing.

For a more detailed examination of these protocols, our guide on how enterprise AI security provides an audit-proof framework for 2025 is an essential resource.

Upholding DSGVO and Ethical Principles

In Germany and across the EU, regulatory compliance is paramount. Any automated system that processes personal data is subject to the strict requirements of the Datenschutz-Grundverordnung (DSGVO/GDPR). This necessitates meticulous attention to data minimisation, purpose limitation, and the rights of data subjects.

Governance is not a barrier to innovation; it is the framework that enables the development of trustworthy automation. By proactively addressing compliance, German businesses can build a powerful competitive advantage based on integrity and reliability.

Beyond legal requirements, clear ethical AI principles are needed to maintain the trust of customers, partners, and employees. This means ensuring that AI-driven decisions are transparent, fair, and, critically, explainable.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

Having a clear strategy for managing operational disruptions is crucial for long-term success. You can learn more about building a robust operational risk management framework to handle these potential events. By treating governance and security as central pillars of your strategy, you can scale automation with confidence and safeguard the future of your organisation.

An Executive Playbook for Strategic Automation

Implementing automation is not simply another IT project; it is a fundamental business transformation. Transitioning from scattered pilots to an enterprise-wide strategy requires a deliberate, phased approach driven by executive leadership.

This playbook consolidates the insights from our industry analyses into a clear roadmap for German organisations. It is designed to help leaders steer the initiative, ensuring every investment delivers measurable, sustainable value. The focus is on three core elements: strategic alignment, cultural integration, and disciplined execution.

Phase 1: Strategic Alignment and Leadership Coalition

First, your automation strategy must be explicitly linked to your core business objectives. Automation for its own sake is a misallocation of resources. It must be a direct answer to a key strategic question. Are you aiming to reduce operational costs, increase market share, or accelerate time-to-market? This link must be clear from the outset.

Ready to Build Your AI Project?

Let's discuss how we can help you ship your AI project in weeks instead of months.

To execute this, assemble a cross-functional leadership team comprising representatives from IT, operations, finance, and HR. This group will serve as the steering committee. Its mandate is to champion the automation agenda, secure necessary resources, and ensure alignment across the organisation.

Phase 2: Prioritisation and Pilot Selection

Once the strategic "why" is established, the next step is to determine the "what" and "where". The objective is to identify high-impact processes that also offer a clear path to a solid return on investment (ROI). A common mistake is to begin with the most complex, entrenched process. This should be avoided.

Instead, target quick wins. These build momentum and provide proof of concept to the wider organisation.

When selecting initial pilot projects, look for these characteristics:

- High Volume and Repetitive Nature: Targeting processes with significant manual effort provides an immediate and demonstrable efficiency gain.

- Low Process Complexity: Begin with stable, rules-based tasks to minimise implementation risk in early stages.

- Measurable Impact: Ensure you can track relevant KPIs before and after implementation. Success must be quantifiable.

These early victories are your most effective internal marketing tool. They build confidence and create a pull-effect, where other departments request automation rather than having it imposed upon them.

Want to Accelerate Your Innovation?

Our team of experts can help you turn ideas into production-ready solutions.

A successful automation programme is built on a series of strategic victories. Each successful pilot functions as an internal case study, creating a pull-effect where other teams actively seek to participate.

Phase 3: Scaling and Cultural Integration

Transitioning from pilot projects to a full-scale rollout is where the human element becomes paramount. Automation changes job roles and daily workflows. Proactive change management is essential. The focus must shift to reskilling and upskilling your workforce. The goal is to transition employees from process executors to process designers and automation managers.

Simultaneously, you must foster a culture of continuous improvement. Encourage your teams to identify automation opportunities within their own workflows, creating a bottom-up innovation engine. Leadership must communicate clearly and consistently that automation is not a threat, but a tool to empower employees to perform more valuable, engaging work.

Finally, establish a robust framework for measuring and communicating success. Define clear metrics that extend beyond cost savings to include improvements in quality, speed, compliance, and employee satisfaction. Regular reporting of these wins maintains momentum and demonstrates the strategic value of the initiative.

A Few Questions We Hear a Lot

When steering your business toward a new operational model with automation, it is natural for significant questions to arise. We understand. Here are concise answers to some of the most common inquiries we receive from leaders in German enterprises, covering investment, risk, and the critical human element.

How do we calculate the true ROI of automation beyond direct cost reduction?

This is a critical question, as the full value of automation extends far beyond labour arbitrage. While cost savings are a clear and immediate benefit, focusing solely on this metric misses the larger strategic impact.

Consider the less tangible but more powerful value drivers:

- Enhanced Compliance and Risk Mitigation: Automation significantly reduces human error in regulatory reporting (e.g., DSGVO/GDPR), which can drastically lower the risk of substantial fines.

- Improved Customer Loyalty: When AI enables faster response times and more personalised service, it directly enhances customer satisfaction and retention.

- Unlocking Human Capital: By automating routine administrative tasks, you free your most skilled employees to focus on high-value activities such as innovation, strategy, and complex problem-solving.

What is the most significant mistake companies make when initiating automation?

The most common error is pursuing technology without a clear business objective. Many organisations adopt automation because it is perceived as a technological imperative. This approach typically results in a collection of isolated, small-scale pilot projects that fail to deliver strategic value.

This is often referred to as "pilot purgatory." A promising trial gets stuck because it does not solve a real, strategic problem for the business. The correct approach is to begin by asking, "Which of our key business objectives can automation help us achieve more effectively?" rather than "What new technology can we implement?"

How should we manage the impact on our workforce?

This is arguably the most critical component of a successful automation strategy. Managing the human side requires a clear, transparent plan focused on workforce evolution, not replacement. The goal is to position the initiative as a collaborative step forward.

Looking for AI Expertise?

Get in touch to explore how AI can transform your business.

Effective strategies include:

- Invest in Reskilling: Allocate resources to training programmes that equip employees with the skills needed to manage, oversee, and work alongside automated systems.

- Maintain Radical Transparency: Communicate the strategic rationale for automation clearly. The objective is to augment human capabilities and grow the company, not to reduce headcount.

- Create New Roles: Identify emerging roles focused on analytics, process optimisation, and managing the complex exceptions that automation cannot handle. This creates new career paths for your existing talent.

At Reruption GmbH, we are not just consultants; we are your co-preneurs in the AI era. We partner with you to build and implement an automation strategy that delivers measurable business results. Let's turn your ideas into real innovations together.